There are so many options available when it comes to surface protection coatings. Finding the ideal protective solution requires considering a variety of elements, as every surface has different requirements. Polyurethane and silicone varnishes are two of the most well-known alternatives, each having its own set of qualities and uses. Through a comparison and contrast of silicone and polyurethane varnishes, we will be able to clarify the differences between the two coats and their possible uses.

Introducing Harman Bawa Pvt. Ltd.: A Commitment to Excellence

Let us first introduce the company that is the source of this conversation before we set out on our quest to understand these varnishes. Regarded as a leader in coatings and protective solutions, Harman Bawa Pvt. Ltd. Harman Bawa has been providing high-quality goods that are customized to fit the various needs of its clients for decades. This is evidenced by its innovative and dedicated legacy. Harman Bawa is a reputable brand in the business because of its persistent dedication to excellence, which is appreciated by both small and large industrial companies.

Understanding Silicone Varnishes

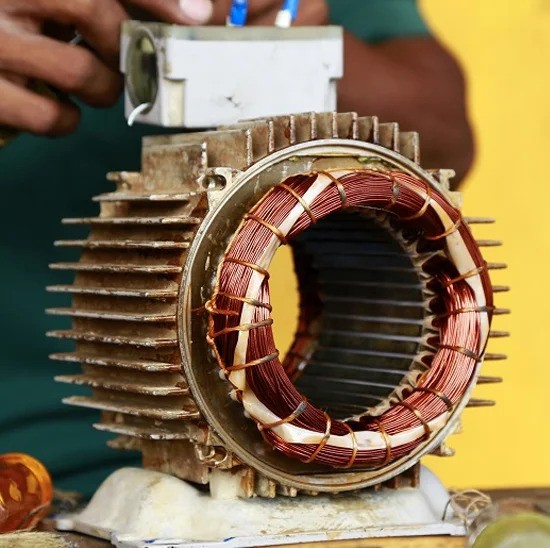

Renowned for their adaptability and resilience, silicone varnishes have established a distinct market niche within the coatings sector. These varnishes, which are derived from silicone polymers, are perfect for a variety of applications due to their many advantages. Their remarkable heat resistance is one of silicone varnishes’ main benefits. Their ability to withstand high temperatures makes them ideal for use in high-temperature environments, like electrical insulating coatings and automotive components.

Furthermore, silicone varnishes have exceptional resilience to weather, which makes them appropriate for outdoor applications subjected to severe weather. Because of their hydrophobic qualities, they deter water, shielding surfaces from rust and moisture damage. Furthermore, silicone varnishes have outstanding adherence to a variety of surfaces, guaranteeing durability and effectiveness.

Our selection of silicone varnishes at Harman Bawa Pvt. Ltd. is painstakingly created to satisfy the highest requirements for performance and quality. Our silicone varnishes offer unmatched protection and dependability, whether they are used to improve the longevity of outdoor constructions or to protect electronic components from heat and moisture.

Unraveling Polyurethane Varnishes

Another iconic product in the protective coatings industry, polyurethane varnishes provide a unique set of benefits to suit a variety of requirements and tastes. These varnishes are highly valued for their remarkable durability and resistance to abrasion, as they are made from polyurethane resins. Polyurethane varnishes produce a hard protective layer that endures abrasion when applied to wood, metal, or concrete surfaces; this makes them perfect for high-traffic areas and surfaces that get a lot of use.

Moreover, polyurethane varnishes are very resistant to chemicals, protecting surfaces from spills, stains, and chemical exposure. Because of this characteristic, they are a well-liked option for uses in commercial settings, laboratories, and industrial environments where chemical resistance is crucial.

At Harman Bawa Pvt. Ltd., we take pleasure in offering a wide variety of polyurethane varnishes that are specially formulated to satisfy each client’s unique requirements. Our polyurethane varnishes offer unparalleled durability and performance in every application, from protecting industrial floors from heavy machinery to enhancing the visual attractiveness of hardwood furniture.

Comparing Silicone Varnishes and Polyurethane Varnishes

Although silicone and polyurethane varnishes are equally effective at offering protection and longevity, they differ in certain ways that make them appropriate for specific uses. Now let’s examine the comparative study in more detail:

Heat Resistance: Silicone varnishes are the better option for applications that are subjected to high temperatures since they have a higher heat resistance than polyurethane varnishes.

Chemical Resistance: Polyurethane varnishes are the most chemically resistant, which makes them perfect for locations where spills and chemical exposure are common.

longevity: Polyurethane varnishes are known for their better abrasion resistance, which makes them appropriate for high-traffic areas even though both varnishes offer outstanding longevity.

Adherence: Silicone varnishes provide superior adherence to a range of substrates, guaranteeing performance and long-lasting protection in a variety of applications.

Aesthetic attractiveness: Polyurethane varnishes frequently offer a smoother finish and improved clarity, boosting the visual attractiveness of materials like hardwood floors and furniture.

The Choice is Yours

Regarding coatings and protective treatments, there isn’t a universally applicable strategy. The selection between polyurethane and silicone varnishes is contingent upon various criteria, including the intended performance qualities, application specifications, and environmental factors. At Harman Bawa Pvt. Ltd., our team of professionals is dedicated to helping you identify the ideal solution for your unique needs since we recognize how important it is to make informed decisions.

Conclusion: A World of Possibilities

The world of coatings is huge and complex, offering a multitude of options for improving and protecting surfaces. This is evident when we reach the end of our investigation of silicone and polyurethane varnishes. An ideal coating may make all the difference, whether you’re protecting electronic components from moisture and heat or giving hardwood furniture a beautiful sheen.

We at Harman Bawa Pvt. Ltd. cordially invite you to join us on an exceptional adventure. Our unparalleled proficiency, state-of-the-art equipment, and dedication to excellence put us in a position to surpass your expectations and fulfill all of your coating requirements. Let’s work together to unleash the potential of silicone and polyurethane varnishes and bring in a new era of excellence, performance, and protection.